Helius Sunlink PV, a manufacturer founded on the pillars of responsibility, quality, and transparency, has increasingly gained recognition in photovoltaic module production. Since the foundation in 2004, the company has been producing the cells used in its modules in-house. On this topic, the company’s Country Manager, Eduard Krummenauer, states that “complete control over the production process ensures superior quality assurance at every stage, delivering reliable and efficient products. Our attention to detail and a continuous drive for innovation guarantee that our modules deliver optimal performance, serving client´s needs with reliability and speed, as our machine setup is significantly streamlined by our internal cell production.”

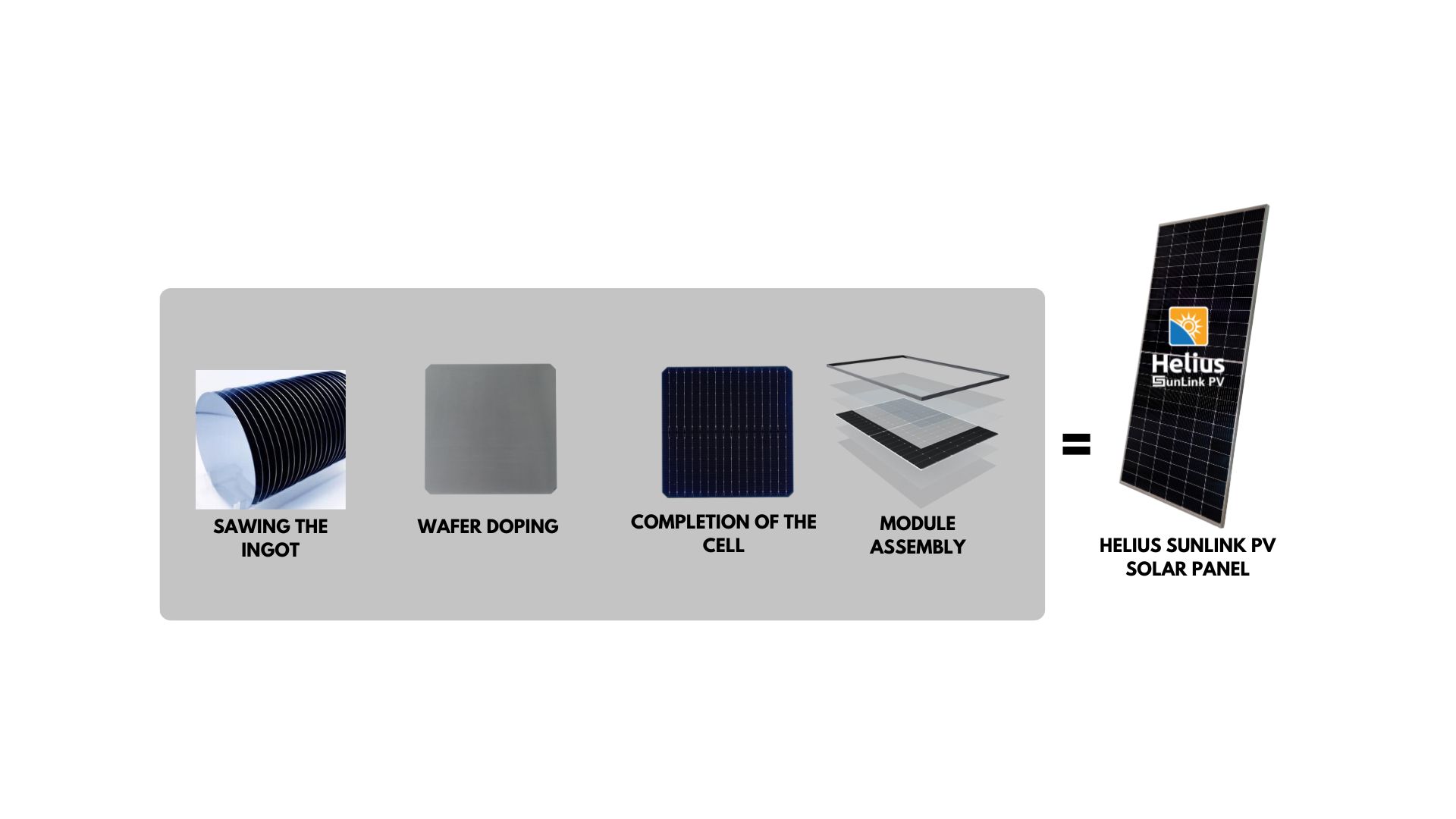

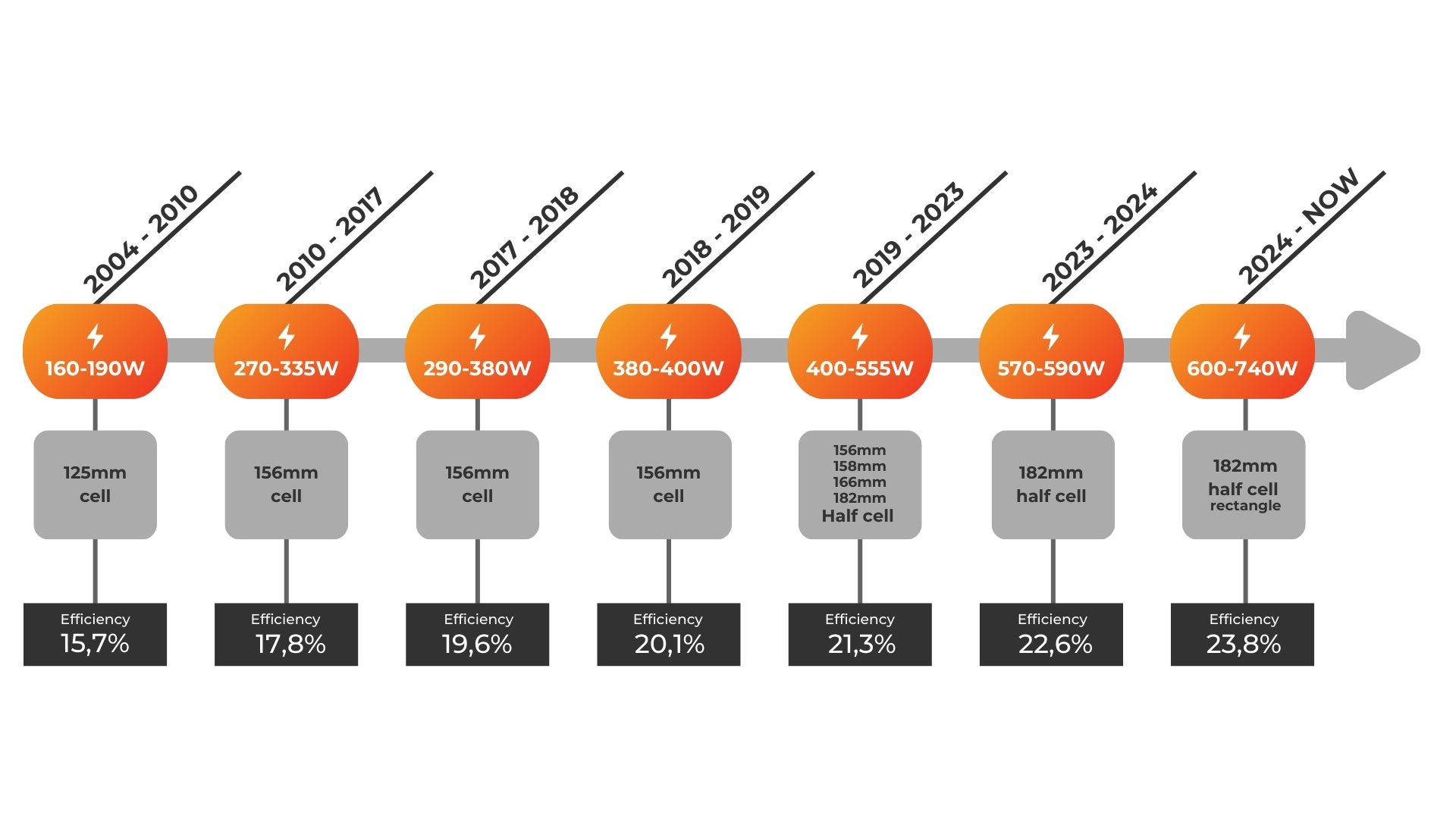

“The cell manufacturing process is meticulous, involving extensive research and dedication. Each step—from silicon ingot slicing, and wafer doping, to the application of electrical contact layers and module assembly—is designed to ensure maximum efficiency and durability. Furthermore, our cell manufacturing has significantly evolved. We started with lower-efficiency cells, but as technology advanced, we increased each cell’s energy generation, aiming for higher power output and performance. Technologies like PERC and Half Cell were also integrated, enabling the expected increase in performance. Nowadays, with cells up to 210mm and cutting-edge N-Type technology, we ensure enhanced reliability and longevity for our products,” Eduard states.

Throughout its 20-year history, Helius has utilized various cell types and sizes, including 125mm, 156mm, 158mm, 166mm, and 210mm. These changes were driven by improvements in the production process and the increasing efficiency of panels, which ranged between 15.7% and 23.8% over the years.

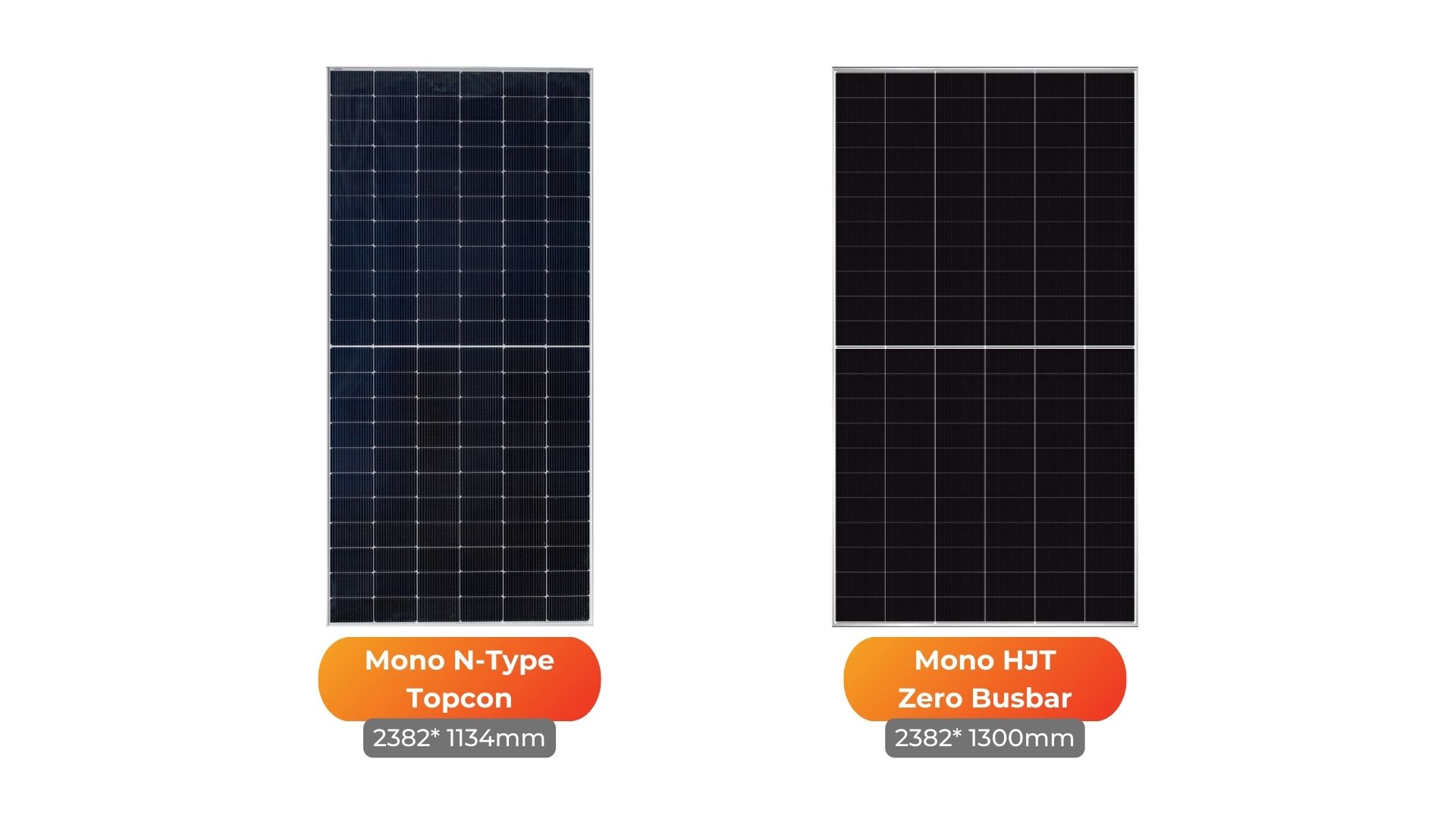

One of the recent advancements Helius implemented in its panels was the use of rectangular cells. This shift was motivated by a key factor: better use of module area. Rectangular cells adapt more effectively to a panel’s geometric format, allowing them to cover almost the entire surface. With this change, Helius modules can deliver more energy per square meter, increasing output power in projects while occupying less area.

At Intersolar 2024, Helius presented its new models featuring cells with Zero Busbar technology. This technology is an innovation in solar cell design, achieved through ultra-thinning of busbars, bringing significant benefits such as higher efficiency, reduced shading, and a cleaner aesthetic. In practice, a module with Zero Busbar technology achieves an efficiency of 23.8% over an area of 3.1m²—an increase of 3.7% in efficiency while maintaining similar dimensions to other models in the portfolio.

Read also: HELIUS 20 YEARS: A Journey Through the Evolution of Photovoltaic Modules

Helius Sunlink PV has been manufacturing solar panels for 20 years and stands out in the industry for its dedication to production quality, precisely by maintaining complete control over the supply chain, from cell manufacturing to module assembly. With a focus on quality, responsibility, and transparency, the company ensures that each panel produced reflects these values.